charpy impact test interpretation|charpy impact test sample : agency Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM CARA COMO RUBI. Conteúdo Hot. Prévias Hot

{plog:ftitle_list}

Resultado da A borboleta faz parte do grupo 4 (quarto grupo) do jogo do bicho de um total de 25 bichos que compõem a tabela do jogo do bicho. A borboleta representa os números 13, 14, 15 e 16 do jogo do bicho, lembrando que pelas regras do jogo do bicho o grupo é formado pelos últimos dois .

charpy impact test sample

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .According to the standard test methods, the Charpy or Izod impact test can be employed to investigate the behavior of specified types of specimens under the impact conditions defined . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specificationsThe Charpy impact test is a common method to measure the toughness of a material, or its ability to resist fracture under impact loading. It involves striking a notched specimen with a pendulum . Each interpretation applies to the Edition stated in the interpretation, or if none is stated, to the Edition in effect on the date of issuance of the interpretation. . ASME B31.3-2006, Table 323.3.4, Charpy Impact Test Temperature Reduction Date Issued: April 29, 2008 File: 08-476 Question: To qualify a material to -46"C, should a 5 mm .While the Charpy Impact Strength test and the Hardness test serve different purposes, they both provide valuable information about a material's mechanical properties. The Charpy Impact Strength test focuses on a material's ability to absorb energy and resist fracture under impact loading conditions, while the Hardness test measures a material's .

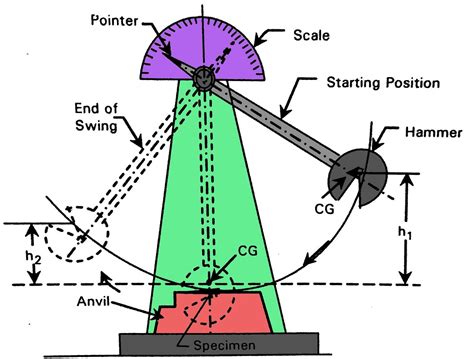

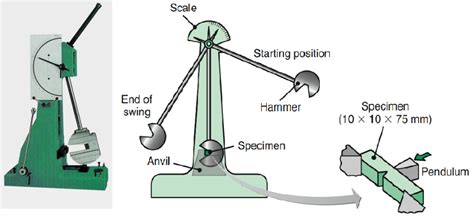

The Charpy impact test must be performed using a calibrated and verified machine, consisting of a rigid frame, a pendulum, a specimen holder, and a dial or digital display. In order to understand the effects of Mn content and test temperature on Charpy toughness, microstructural analysis of the Charpy impact specimens is essential. Since the Charpy impact specimen is rapidly fractured by crack initiation and propagation processes, the plastically deformed area is quite small even at the notch-tip region, which .4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces. 7 Recommendations for specifying impact strength requirements in steel specifications. . 7.4 Interpretation of .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

Interpretation of results - Charpy test Interpretation of results - Charpy test Braham0123 (Mechanical) (OP) 8 Sep 20 17:14. Hello; I am doing professional internships in a company that supplies steel. . If the CVN impact test had complied with (1) & (2) above, the tests are passed because the test results have sufficient tolerable margins. .

Abstract. The Charpy V-notch (CVN) impact test has been widely used by operators and pipe mills to measure steel pipe resistance to fracture propagation. The tests are generally conducted at multiple temperatures to capture the transition from low impact energy nonductile regime to the high impact energy ductile regime. Due to the limitation of wall .

I'm working on NGL pipelines and pump stations (B31.4) and have had several discussions on the interpretation of the Charpy impact test requirements in section 423.2.3. The code states "Steel pipe designed to be operated at a hoop stress of more than 20% SMYS shall be impact tested in accordance with the procedures of API 5L, PSL 2, or ASTM A333.

The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).A Charpy impact test is a common way to measure the toughness of a material, or its ability to absorb energy before breaking. Toughness is an important property for many engineering applications . A split Hopkinson pressure bar was used for dynamic compressive tests [17], [18], whose schematic diagrams are presented in Fig. 1.Cylindrical specimens (size; 5Φ×5 mm) used for dynamic compressive tests were prepared in parallel to the rolling direction so that the specimen orientation was matched with the pendulum-impact direction of the Charpy impact .

scope: This document specifies a method for determining Charpy impact properties of plastics from force-deflection diagrams. Different types of rod-shaped test specimens and test configurations, as well as test parameters depending on the type of material, the type of test specimen and the type of notch, are defined in ISO 179-1.

charpy impact test procedure

impact is applied to the face directly behind the notch using the blow from a swinging pendulum hammer. The impact testing machine calculates the energy absorbed, which can be converted to impact strength using the following equation: impact strength = energy absorbed area under the .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

We provide comprehensive testing services through our network of accredited labs around the US and skilled consultants, including doorstep sample pickup and delivery, in-depth analysis, and test result interpretation. An important test in material science is the ASTM D6110 Charpy Impact Resistance Test for Notched Specimens of Plastics.The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.Charpy Test The Charpy test is a good way to measure material toughness. It is useful for materials that exceed the 10.mm (0.394.inches) Charpy height. Specimens can also be made in ¾, and ½ sizes so in theory a 0.20 inch thick specimen can be produced. The Charpy specimen is relatively easy to make and test. ASME B31.3 2006, Table 323.3.4, Charpy Impact Test Temperature Reduction. . Interpretation Number : 22-02. Question(s) and Reply(ies): Question: To qualify a material to 46C, should a 5 mm Charpy impact specimen produced from a 6.32 mm material thickness be tested at 50.1 C?

The Interpretation of Charpy Impact Test Data Using Hyper-Logistic Fitting Functions By JL Helm JL Helm 1. Assistant Professor , Department of Applied Physics, . The hyperbolic tangent function is used almost exclusively for computer assisted curve fitting of Charpy impact test data. Unfortunately, there is no physical basis to justify the . The Charpy V-notch (CVN) impact test is a method of characterizing a line-pipe material`s notch toughness and resistance to fracture growth. Although CVN testing of line pipe material is routine, test results are sometimes misinterpreted because of specimen size and load rate on actual toughness transition behavior. Abstract. The Charpy V-notch (CVN) impact test has been widely used by operators and pipe mills to measure steel pipe resistance to fracture propagation. The tests are generally conducted at multiple temperatures to capture the transition from low impact energy nonductile regime to the high impact energy ductile regime. Due to the limitation of wall .

%PDF-1.5 %âãÏÓ 1381 0 obj > endobj 1397 0 obj >/Filter/FlateDecode/ID[99F09C433BA3E74FAFD6B5679B801655>10D0DE9B1FDC084D81D228EB77CDEE20>]/Index[1381 42]/Info 1380 . I'm working on NGL pipelines and pump stations (B31.4) and have had several discussions on the interpretation of the Charpy impact test requirements in section 423.2.3. The code states "Steel pipe designed to be operated at a hoop stress of more than 20% SMYS shall be impact tested in accordance with the procedures of API 5L, PSL 2, or ASTM A333.

Digital Display Tensile Tester factories

WEB25 de out. de 2018 · A história nos remete à profunda reflexão sobre o que uma guerra proporciona. Vale destacar que o diretor Isao Takahata ( 1935 – 2018 ) é co-fundador do Estúdio Ghibli, e entre outros projetos, em 2013 estreou no Japão o Conto da Princesa Kaguya. Este filme recebeu indicação ao Oscar e estreou em 2015 no Brasil.

charpy impact test interpretation|charpy impact test sample